EQUIPMENT SALES

Original Equipment Designed and Developed In-house

Using equipment that we ourselves have designed, we have a proven track record in taping orders ranging from small quantities to over 100 million units. We also design, manufacture, and sell equipment that isn’t related to taping, such as assembly and inspection equipment.

We offer a variety of styles to meet our customers’ needs.

We offer a variety of styles to meet our customers’ needs.

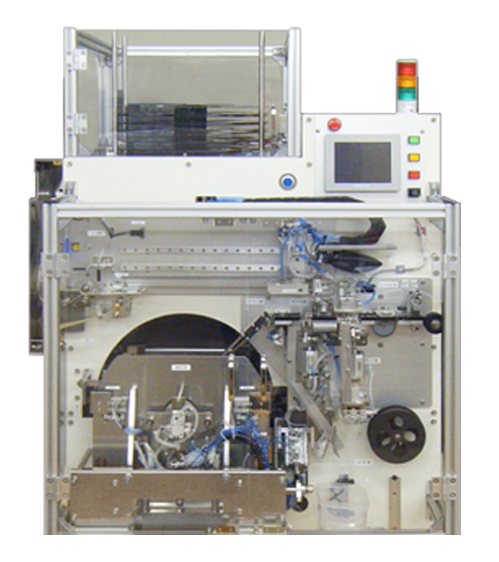

Automatic Reel Changer

ERC-380L(R)

An original machine with fully automatic reel winding and changing

Continuous winding is possible without stopping the taping machine.

Reduces the manpower required for reel replacement and contributes to cost reduction.

Continuous winding is possible without stopping the taping machine.

Reduces the manpower required for reel replacement and contributes to cost reduction.

Main Features

- Empty reels can be replenished and completed reels can be taken out without stopping the taping machine

- Fold-back Kraft tape can be affixed

- Fold-back Kraft tape can be affixed

- Reel outer diameter: 180, 254, 330, and 380 mm

- Tape width: 8, 12, 16, 24, 32, 44, and 56 mm

- Insertion pitch: 4, 8, 12, 16, and 24 mm (switchable with numerical settings)

- Tape width flow direction: Left or right

- Tip processing: Inserted into reel or affixed with Kraft tape

- End processing: Affixed with special end tape or (fold-back) Kraft tape

- Trailer length: 100 to 230 mm (switchable with numerical settings)

- Leader length: 100 to 400 mm (switchable with numerical settings)

- Compatible carrier tape: 0.2 to 0.4 mm thick

- External dimensions: 900 mm (width) x 1700 mm (height) x 1000 mm (depth)

Other customizations are available upon request. Please feel free to contact us.

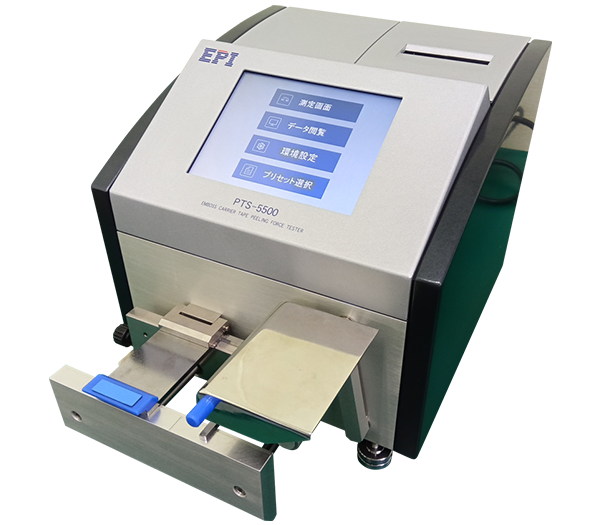

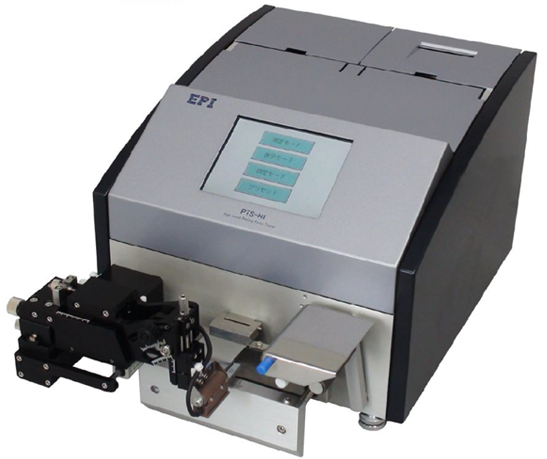

Peel Strength Tester

PTS-5500

Our original peel strength tester has been adopted as the industry standard.

Our original peel strength tester has been adopted as the industry standard.

Our original peel strength tester has been adopted as the industry standard.

Main Features

- Our unique peeling mechanism enables peel strength testing up to 7.5 m in a small space.

- Since the peeling angle is constant, the measurement data is reproducible.

- Peel strength can be set according to JIS standards. Variable from 120 to 300 mm/min.

- The LCD touch panel display makes it easy to set detailed conditions.

- Maximums, minimums, means, standard deviations, CPKs, and all data are compiled. Easy lot management.

- Equipped with a printer to output totals, graphs, numerical values, measurement conditions, taping conditions, memos, etc.

- A graph is displayed on the screen during measurement. A timer can also be set so that the measurement is fully automated once started.

- Switchable between Japanese, English, and Chinese.

- Switchable between gf display and N display.

- Data transferable to PC via USB.

Other customizations are available upon request. Please feel free to contact us.

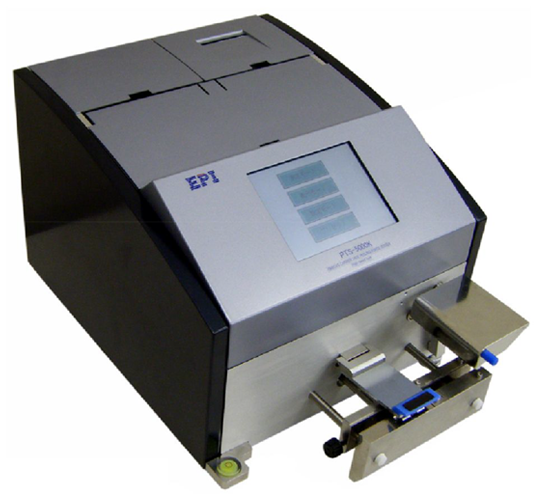

High-speed Peel Strength Tester

PTS-5000K

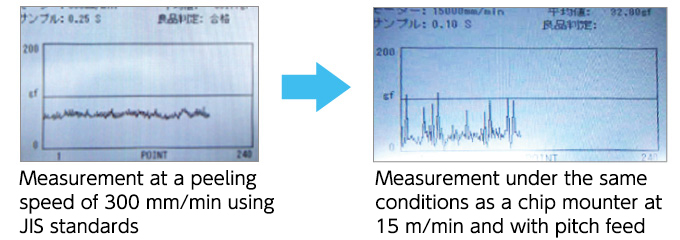

Measured at the same peeling speed as a high-speed chip mounter

The PTS-5000K can achieve the true quality required in taping.

The PTS-5000K can achieve the true quality required in taping.

Main Features

- Our unique peeling mechanism enables measurement of long samples at a high feed rate (15 m/min).

- Measurement can be performed during continuous operation and pitch feed operation, and with pitch feed, measurement can be performed under the same operating conditions as the chip mounter.

- Measurement data can be output in analog form for more detailed analysis.

- The feed rate can be varied from 120 mm to 15 m/min, and JIS standard measurement of 300 mm/min is also possible.

Other customizations are available upon request. Please feel free to contact us.

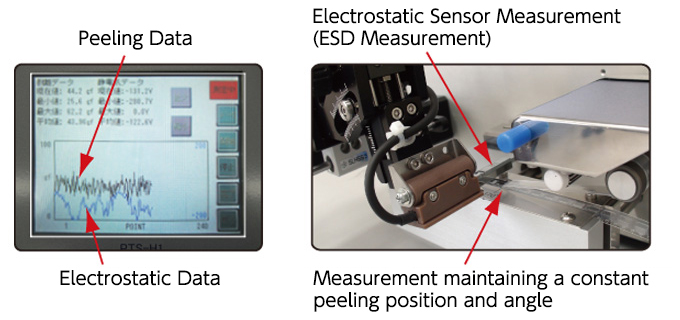

High-speed Peel Strength Tester with Electrostatic Sensor

Peeling and electrostatic measurements can be performed simultaneously at the same peeling speed as that of a high-speed chip mounter.

Main Features

- Our unique peeling mechanism enables measurement of long samples at a high feed rate (15 m/min).

- Measurement can be performed during continuous operation and pitch feed operation, and with pitch feed, measurement can be performed under the same operating conditions as the chip mounter.

- Measurement data can be output in analog form for more detailed analysis.

- The feed rate can be varied from 120 mm to 15 m/min, and JIS standard measurement of 300 mm/min is also possible.

Other customizations are available upon request. Please feel free to contact us.